Product Introduction

Product Description

The Automatic Winding Filter Is Actually A New Type Of Air Filtration Equipment, Which Converts The Pressure Difference

Before And After The Filter Into A Sensing Signal And Realizes The Automatic Equipment Of Filter Material Replacement

Working Principle

The New Filter Material Is Installed In The Filter Material Box. After The Air Intake Of The Air Conditioner Carries A High

Concentration Of Dusty Air Through The Winding Filter, The Initial Resistance Of The Filter Gradually Increases With

The Increase Of Filter Dust. When The Filter Resistance Rises To The Set Final Value, The Differential Pressure Switch Acts,

The Controller Receives The Running Signal, Immediately Switch On The Motor Power, And Automatically Start The Motor.

The Motor Operation Drives The Filter Material Scroll To Rotate, So As To Roll Up The Dirty Filter Material, And Replace

The Filter Surface With Clean Filter Material. The Displacement Of The Filter Material Replacement Is Controlled By

The Lower Pressure Difference Switch. When The New Filter Material Is Replaced, The Pressure Difference Resistance

Of The Equipment Will Decrease. When The Air Pressure Drops To The Value Set By The Lower Pressure Difference Switch,

The Plc Sends Instructions To The Motor And The Motor Stops Working.

Application Scenario

It Can Be Used For Blower Inlet Air Filtration In Sewage Treatment Plants, Air Conditioning Return Air System In Textile Factories,

Industrial Ventilation For Cooling Equipment, Pre-Filtration Section Of Central Air Conditioning, Subway Civil Air Defense

Engineering And Other Environments Requiring Frequent Replacement Of Initial Effect

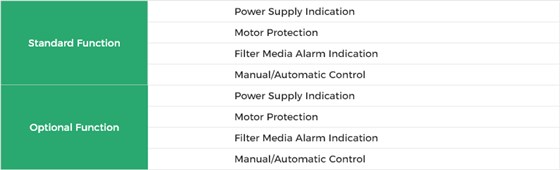

Control Function Detail